POSTALLOY® Tubular Electrodes are filled with the highest percentage of carbide forming alloys for maximum wear resistance and longest service life of your equipment.

Benefits of POSTALLOY® Tubular Electrodes Hardfacing Products include:

- Reduced distortion

- Reduced dilution improves the performance of the first layer

- Minimized risk of burn-through

- Allows hardfacing thin edges

- Reduces power consumption

In addition to Tubular Electrodes, Postle Industries offers a complete line of Hardfacing Products engineered for maximum service life of your equipment.

| Product Type: Flux-coated Tubular Electrode Description:Postalloy® 150HD Vanguard is a tubular hardfacing electrode that provides a dense, heterogeneous deposit of vanadium - tungsten carbides, along with other elements to enhance wear resistance, resulting in a very good combination of abrasion and impact resistance. This makes it superior to chromium carbide hardfacing alloys and almost equal to tungsten carbide in hardness at half the weight. Postalloy Vanguard 150HD is not a replacement for tungsten carbide overlays. However, it is a good alternative to tungsten carbide hardfacing alloys when they are too expensive or when MIG carbide embedding is not available or impractical. Unlike straight tungsten carbides, which are heavy and forced to the bottom of the weld puddle, the composition of Postalloy®150HD Vanguard is ideally balanced to provide a uniform distribution of vanadium - tungsten carbides throughout a tough steel matrix that takes more impact than both chromium and tungsten carbides. Also, it provides a very consistent wear rate and is designed for multiple re-applications. An excellent choice for many different hardfacing applications including mining, construction, recycling, dredging, forestry and sugar industries. Postalloy® 150HD Vanguard Product Details |

Typical Applications

Ammonia injector knives Conveyor screws Ditch and trenching teeth Debarking hammers Augers Shredder and Fibrizer hammers Drill collars Dozer end bits Grinding equipment Recycling wear parts Stabilizers Shovel bucket sides, lips, teeth and adaptors Rippers Shredder hammers Sub-soilers Sugar cane cutting knives (Cuchillas) Sugar cane hammers Fibrizer cane hammers (Martillo) 150HD Vanguard Data Sheet |

| Product Type: Flux-coated Tubular Electrode

Description: Postalloy® 210HD is formulated with a high percentage of Chromium Carbide producing a tubular hardfacing electrode that is highly resistant to abrasion with mild or moderate impact. Weld deposits are smooth and take on a high polish to resist sliding particle abrasion. It can be apllied to carbon and alloy steels, as well a cast iron. High Compressive Strength - Deposits do not tend to shatter and spall off under conditions of high impact. Ideal for gouging abrasion. Hardness at Elevated Temperatures - The hardness and wear resistance of Postalloy 210HD is maintained up to 1000°F(538°C). Welding characteristics are outstanding - Postalloy® 210HD can be used on any type of welding machine, either AC or DC, in both flat and vertical positions. Postalloy® 210HD Product Details |

Typical Applications

Swing hammers

Fixed hammers Shovel buckets Crusher rolls (rock & shale) Muller tires |

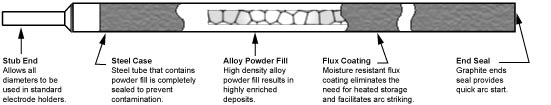

| Product Type: Flux-coated Tubular Electrode Description:Postalloy® 215HD is a chromium carbide tubular hardface electrode for hardfacing low carbon mild and alloy steels, manganese steel, stainless steel and cast iron. It's tubular structure permits higher travel speeds and much higher percentages of carbide forming elements contained in the core than with ordinary flux-coated electrodes. Due to its unique tubular design, Postalloy® 215HD offers very smooth operational characteristics and is over 90% efficient. All of the 1/4", 3/8" and 1/2" diameters will fit standard electrode holders. |

Typical Applications

Mining and construction screw conveyors Dozer end bits |

| Product Type: Flux-coated Tubular Electrode Description:Postalloy® 216HD (Chapisco), for Roll-Arcing, is primarily engineered for the sugar cane industry and is to be used while the sugar cane roll is rotating. Postalloy® 216HD produces a rough weld deposit that will aid in pulling, tearing and crushing the sugar cane as it feeds through the rolls during processing. Also used for sugar mill rolls hooks (Picote). |

Typical Applications

Sugar mill rolls (Chapisco)

|

| Product Type: Flux-coated Tubular Electrode Description:Postalloy® 217HD is modified Chromium Carbide tubular hardfacing electrode, alloyed with Niobium and a small addition of Molybdenum. The microstructure has very fine carbides which give improved wear, errosion and impact resistance over traditional Chromium Carbides. It is designed for applications that require more abrasion resistance than Postalloy® 215HD. The Carbide concentration is denser and slightly harder but less brittle than Postalloy® 215HD providing a better, more wear-resistant surface. |

Typical Applications

Mining and quarry equipment Excellent final layer on manganese jaw crushers and swing hammers |

| Product Type: Flux-coated Tubular Electrode Description:Postalloy® 218HD produces a multi-carbide weld deposit that resists many types of wear. The weld-deposit. is a tightly packed, dense, inter-connected network of chromium carbides, vanadium carbides, molybdenum carbides, niobium carbides and tungsten carbides. Weld deposits offer exceptional wear resistance to general abrasion, high stress grinding, low stress scratching and erosion. Impact resistance is limited. This alloy may also be used at elevated temperatures up to 1300°F (700°C). First pass hardness is greater than other hardface electrodes - 65Rc on mild steel. Other outstanding features include: |

Typical Applications

Solid waste shredder parts Cement mill parts |

| Product Type: Flux-coated Tubular Electrode alloyed with Tungsten Carbide and Chromium

Description: TUNGSTEN CARBIDE TUBULAR ELECTRODE When protection with tungsten carbide is needed, Postalloy® 219HD is an ideal choice. Weld deposits contain tungsten carbide in a chromium cobalt rich matrix, providing a good combination of abrasion resistance with impact toughness. Other features include: • Easy out-of-position weldability with the 1/4" diameter • Excellent AC or DC operation, even on a "buzz box" • Low amperage and high metal recovery - no slag to chip • High deposition rates - up to 3 times faster than ordinary electrodes • Moisture resistant coating, even under severe weather or high humidity Postalloy® 219HD hardfacing is a unique concept in hard facing technology and is over 90% efficient. It's tubular design offers very smooth operational characteristics and permits higher travel speeds and much higher percentages of carbide forming elements contained in the core as compared to ordinary flux-coated electrodes. Postalloy® 219HD Product Details |

Typical Applications

Auger points Debarking hammers Cutter and dredge teeth Tamping tools Bucket pin ends

Shredder and anvil knives Muller plows Mixer paddles and fan blades Dredge teeth 219HD Data Sheet |

| Product Type: Flux-coated Tubular Electrode alloyed with Tungsten Carbide, Cobalt and Chrome

Description: TUNGSTEN CARBIDE TUBULAR ELECTRODE Postalloy® 220HD contains increased levels of tungsten carbide compared to Postalloy® 219HD, with additional chrome and cobalt for toughness. The unique blend of Tungsten Carbide and Chrome provides a high polish in service to reduce the coefficient of friction. When protection against severe abrasion is needed, Postalloy® 220HD is an ideal choice. • Easy out-of-position weldability with the 1/4" diameter • Excellent AC or DC operation, even on a "buzz box" • Low amperage and high metal recovery - no slag to chip. Postalloy® 220HD is over 90% efficient. • High deposition rates - up to 3 times faster than ordinary electrodes • Moisture resistant coating, even under severe weather or high humidity Postalloy® 220HD Product Details |

Typical Applications

Conveyor screws and augers

Cutter and dredge teeth Mixer paddles and blades Shredder and anvil knives |

| Product Type: Flux-coated Tubular Electrode Description: Postalloy® 233HD is a chromium carbide tubular hardface electrode with the addition of niobium. The addition of this alloy improves the abrasion resistance of the weld deposit. It's tubular structure permits higher travel speeds and much higher percentages of carbide forming elements contained in the core than with ordinary flux-coated electrodes. Due to its unique tubular design, Postalloy® 233HD offers very smooth operational characteristics and is over 90% efficient.Weld deposit chemistry consist of chromium and niobium carbides combined in such a way as to produce extremely good abrasion resistance coupled with mild to moderate impact resistance. Deposits take on a high polish to resist sliding particle abrasion and will maintain good hot hardness up to 1000°F (538°C). * Easy out-of-position weldability with the 1/4" diameter * Excellent AC or DC operation, even on a "buzz box" * High metal recovery - no slag to chip * Low amperage and high deposition rates - up to 3 times faster than ordinary electrodes * Moisture resistant coating, even under severe weather or high humidity. Postalloy® 233HD Product Details |

Typical Applications

Mining and construction screw conveyors Dozer end bits |

| Product Type: Flux-coated Tubular Electrode

Description: Postalloy® 243HD is modified Chromium Carbide tubular hardfacing electrode, alloyed with Niobium and a small addition of Molybdenum. The micro structure has very fine carbides which give improved wear, erosion and impact resistance over traditional Chromium Carbides. It is designed for applications that require more abrasion resistance than Postalloy® 215HD. The Carbide concentration is denser and slightly harder but less brittle than Postalloy® 215HD providing a better, more wear-resistant surface. • Easy out-of-position weldability with the 1/4" diameter • Excellent DC operation. • High metal recovery - no slag to chip. Postalloy® 243HD is over 90% efficient. • Low amperage • High deposition rates - up to 3 times faster than ordinary electrode • Moisture resistant Postalloy® 243HD Product Details |

Typical Applications

Mining and quarry equipment Dredge bucket lips and teeth Scraper and grader blades Crusher mantles and liners Screw conveyors Palm oil crusher rolls Excellent final layer

on manganese jaw crushers and swing hammers

The 1/4" size is ideal for vertical, edge and stringer beads 243HD Data Sheet |

| Product Type: Flux-coated Tubular Electrode

Description: Postalloy® 6710HD is modified Complex Niobium Chromium Carbide tubular hardfacing electrode, alloyed with a small addition of Molybdenum. The micro structure has very fine carbides which give improved wear, erosion and impact resistance over traditional Chromium Carbides. It is designed for applications that require more abrasion resistance than Postalloy® 215HD. The Carbide concentration is denser and slightly harder but less brittle than Postalloy® 215HD providing a better, more wear-resistant surface. • Easy out-of-position weldability with the 1/4" diameter • Excellent DC operation. • High metal recovery - no slag to chip. Postalloy® 6710HD is over 90% efficient. • Low amperage • High deposition rates - up to 3 times faster than ordinary electrode • Moisture resistant Postalloy® 6710HD Product Details |

Typical Applications

Mining and quarry equipment Dredge bucket lips and teeth Scraper and grader blades Crusher mantles and liners Screw conveyors Palm oil crusher rolls Excellent final layer

on manganese jaw crushers and swing hammers

The 1/4" size is ideal for vertical, edge and stringer beads 6710HD Data Sheet |

| Product Type: Oxy-acetylene: Bare tubular electrode rod for oxy-acetylene applications Description: BT 2954 is a iron based bare tubular rod for oxy-acetylene applications manufactured with over 60% tungsten carbide particles. It is an ideal solution for extreme abrasion resistant applications and moderate to low impact. Also, good for metal-to-earth applications involving extreme abrasion and moderate to low impact. It is well suited for applications requiring thin deposits. It can be applied to carbon and low alloy steels. Can be used in hot wear applications up to 900°F (482°C) . Postalloy® BT 2954 Product Details |

Typical Applications

Grain mill hammers, agricultural implements, cane knives,drill bits and reamers, tunnel boring heads.

|

| Product Type: Oxy-acetylene: Bare tubular electrode rod for oxy-acetylene applications Description:BT Chromalloy is a chromium carbide bare tubular rod for oxy-acetylene applications. It is an ideal solution for extreme metal to earth applications. It offers excellent abrasion resistance with mild or moderate impact. It is well suited for applications requiring thin deposits. Excellant for application to tillage tools. It can be applied to carbon, low alloy and manganese steels. Can be used in hot wear applications up to 900°F (482°C) . Postalloy® BT Chromalloy Product Details |

Typical Applications

Sand chutes Plowshares |

| Product Type: Flux-coated Tubular Electrode Description:Postalloy® Nico-Tek is a superior non-cracking tubular cast iron electrode using state of the art manufacturing and coating technology to produce a welding electrode that is suitable for joining and surfacing various grades of cast iron. Ideal for heavy weldments and filling in deep cavities. Nico-Tek produces a weld deposit with lower weld shrinkage stress which reduces the possibility of weld or heat-affected zone cracking. Nico-Tek has excellent arc-gouging action that penetrates through surface contamination. The easily controlled weld metal results in crack-free, spatter free weld deposits with no undercutting. Base metal should be pre-heated to 400° F (204° C). 1/4" diameter tubular electrode operates at 90 to 120 amps... the same as a standard 1/8" diameter flux coated electrode. Tubular construction allows it to be used at lower amperage. Tubular electrodes resist overheating. Creates dense deposits on dirty, oil soaked cast iron. Low amperage prevents heat rise in casting. Weld layers can be easily filled or machined. Postalloy® Nico-Tek Product Details |

Typical Applications

Castings, Cast Iron, Valves, Machine Parts |

or contact your local distributor.